In workshops, production halls, or laboratories, fires usually start where heat, electricity, and materials converge: on machines, compressors, control cabinets, or in areas with dust and oil contamination.

Even a single technical defect can be enough to paralyze operations—and with it, deadlines, supply chains, and entire production processes.

Only about a third of all affected companies survive a fire. 43% of companies that cannot immediately resume operations go bankrupt – another 28% fail within the next three years. The survival rate is alarmingly low and demonstrates how crucial preventative fire protection is for a company’s future.

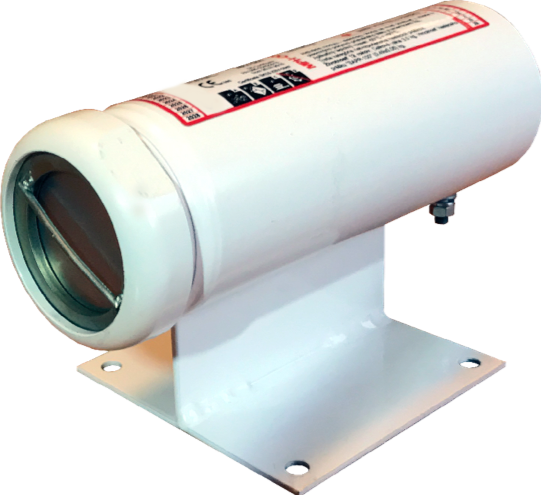

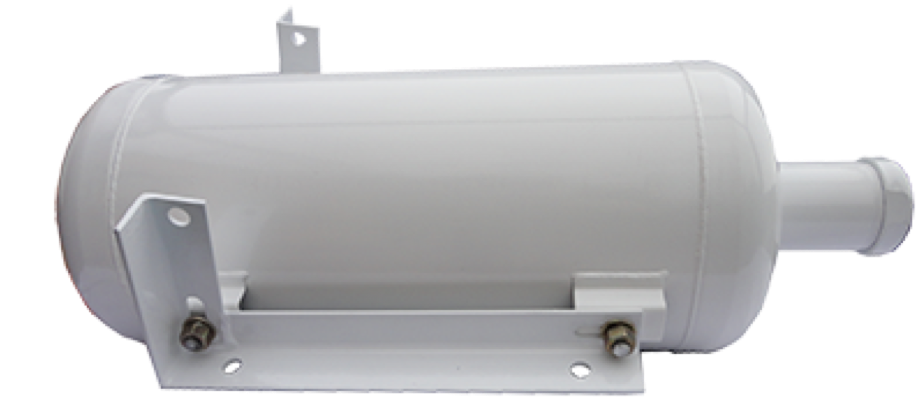

TUNGUS was developed precisely for such scenarios. Our modules react automatically to dangerous temperature increases and extinguish the fire before it can spread.

The specially developed extinguishing powder has a dual effect: it reliably extinguishes flames and wets surrounding areas, thus preventing them from becoming fire-prone. This means fires are not only extinguished but also sustainably contained – a crucial difference compared to conventional systems.

The powder is environmentally friendly, non-toxic, and non-conductive. It can be easily vacuumed up without damaging machinery, equipment, or electronics. This often allows production to resume shortly after the incident – without downtime or consequential damage.

Because industrial applications are so diverse, all TUNGUS modules are used in this sector. Whether individual machines, sections, or complete production lines: TUNGUS offers protection of any scale – for the safety of your employees and the future of your company.

Individual consultation & offers